Glove molding

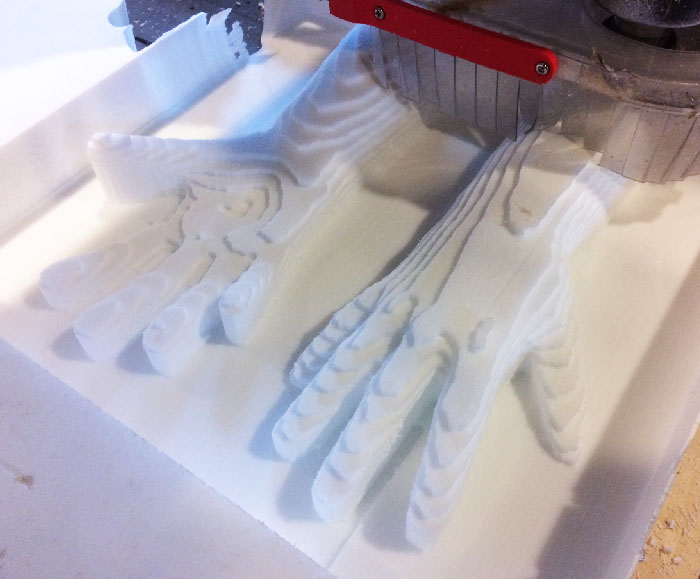

For the Fabricademy textiles as scaffold assignment, I made a glove mold with the cnc for a right hand glove, but I also wanted to make a left hand glove. I wanted to use a different technique this time as I wasn’t completely satisfied with how it turned out: since it was two parts that weren’t exactly each other’s halves, exactly aligning the gloves wasn’t possible. This time I wanted to make a full 3D model. While milling the previous glove mold, I really liked what the mold looked like after the first run (see below):

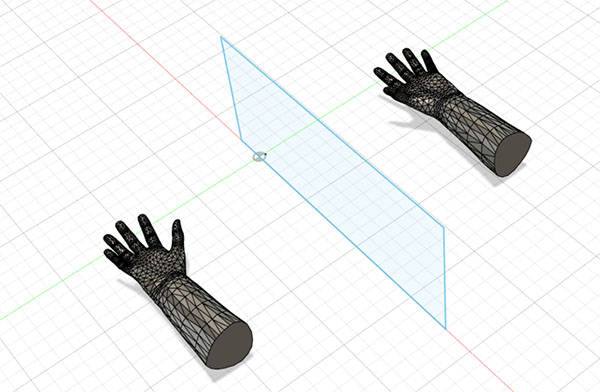

This result can easily be achieved with the slicing and stacking method from the digital bodies assignment, so I mirrored the glove model (without the base) in Fusion360 and exported the left glove model as stl.

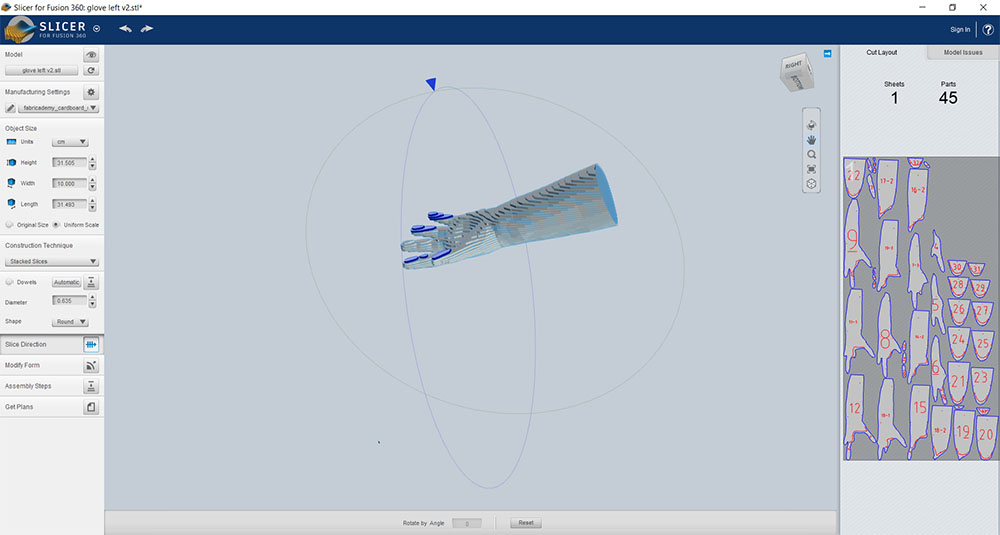

After that I imported the stl in Slicer for Fusion360, specified the cardboard and model size and played around with the stacking angle. Then I exported the plans as dxf, moved around the shapes in Illustrator to save space and closed the polylines in Rhino with the _make2D command in the top view window.

Lasercutting

Settings used for lasercutting the cardboard:

| Settings | Power | Speed | Notes |

|---|---|---|---|

| Cut | 100 | 80 | This went really slow and kind of burned the edges |

| Cut | 100 | 120 | This went fine, it seemed to go 5 times as fast as speed 80 somehow (something weird with exporting maybe?) |

| Cut | 10 | 400 | For very light engraving |

| Cut | 20 | 400 | For light engraving |

Assembled: